In modern automotive lighting, LED headlights have quickly become the preferred choice due to their superior energy efficiency, longevity, and sleek design. As LED technology advances, automotive lighting performance has significantly improved, offering drivers enhanced safety and clarity on the road. However, with a wide variety of LED headlight chips available, understanding their specific features and applications is crucial for selecting the most suitable lighting solutions.

In this blog, we will explore the five main types of automotive LED bulb chips, highlighting their technical aspects and the pros and cons of each to help you make an informed decision when choosing the right LED headlights for your vehicle.

Five Common Types of Automotive LED Bulb Chips

The bulb chip is the core component of LED headlights, responsible for converting electrical energy into light. The bulb chip is primarily composed of LED chips, which generate photons through the recombination of electrons and holes in semiconductor materials, thereby emitting light. The design and quality of the bulb chip directly impact the brightness, color temperature, light efficiency, and lifespan of the bulb.

COB (Chip On Board)

COB (Chip On Board) technology integrates multiple LED chips directly onto the same circuit board, achieving high-density light output. This technology allows for the concentration of LED chips in a limited space, providing uniform light distribution, reducing light spots and shadows, while saving space and typically offering high cost-effectiveness.

However, this technology is not without its challenges. The concentrated arrangement of LED chips generates a significant amount of heat, requiring effective thermal management to prevent overheating and maintain the performance and lifespan of the fixture. Additionally, the dense light source layout may lead to glare issues, and COB technology’s performance might be limited in high-brightness applications.

Despite these challenges, COB technology continues to demonstrate broad application potential in the automotive lighting market, particularly excelling in low to medium power fixtures. Its uniform light distribution and cost efficiency make it popular among consumers, even though its performance in high-brightness applications still requires improvement.

| Pros | Cons |

| Cost-effective | Relatively lower brightness Shorter lifespan Potential glare |

Flip Chip

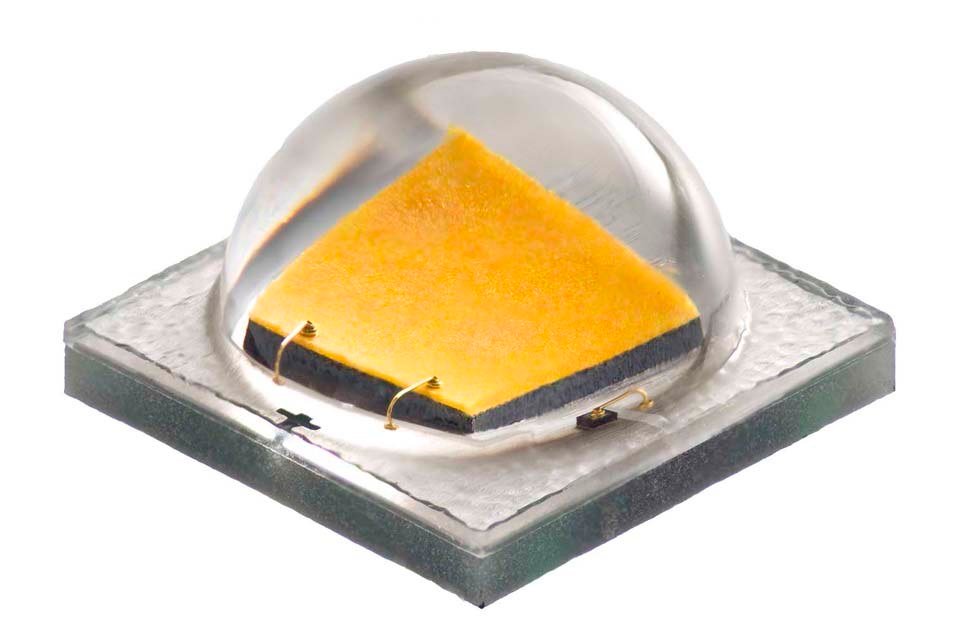

In Flip Chip technology, the LED chip is mounted upside down, with its base directly soldered to the circuit board, eliminating the need for traditional metal leads. This simplifies the packaging process and enhances performance.

Flip Chip technology reduces light loss, allowing more light to emit directly from the chip’s surface, improving efficiency. The direct chip-to-board contact increases thermal conductivity, lowers thermal resistance, and enhances heat management. This is crucial for the stability and longevity of automotive LED bulbs in high-temperature, high-load conditions. Additionally, removing wires and solder points reduces mechanical and thermal stress, further boosting reliability and durability.

| Pros | Cons |

| Improved Light Efficiency Increased Reliability | Complex Manufacturing |

CREE

In the LED industry, CREE is renowned for its high performance and energy efficiency, providing bright and clear light without causing glare.

With over 25 years of industry experience, CREE LED chips have become the preferred choice across various markets, from automotive to household appliances, and from indicators to high-end lighting systems.

In automotive lighting, CREE chips primarily come in two types: XHP5.0 and XPG3.5. Here are their characteristics:

XHP5.0 Chip: This is a high-power single chip with a package size of 5.0 x 5.0 mm, with a power rating of up to 19W per chip. In automotive LED headlights, each bulb typically contains two of these chips, with a total power of about 25-27W per bulb.

XPG3.5 Chip: This is a low-power single chip with a package size of 3.5 x 3.5 mm, with a maximum power of 6W per chip and a maximum luminous efficacy of 146LM/W. In LED headlights, each side uses two of these chips, with a total power of about 26W per bulb.

| Pros | Cons |

| High focus brightness Improved visibility with high beams | Limited power and brightness Compatibility issues with low beam installation |

Philips ZES Chip

The LUXEON Z ES LED, with dimensions of 1.6mm x 2.0mm, is distinguished as a high-power lighting solution, providing exceptional color consistency, luminance, flux density, and design flexibility. Its flat design offers superior optical flexibility, allowing for precise control over beam angles.

Thanks to its straightforward internal structure (with no alloy wire between the chip and the holder) and unique packaging process, the Philips ZES has a lower defect rate compared to other chip types. Furthermore, the compact size and high luminance of the ZES LED enable the creation of specialized LED arrays in headlight bulbs, closely resembling the filament style of halogen bulbs.

| Pros | Cons |

| Excellent beam focus Clear cutoff line | High cost |

CSP (CHIP SCALE PACKAGE)

CSP (Chip Scale Package) is a packaging technology derived from integrated circuit packaging, where the chip area exceeds 80% of the package area. This design minimizes material waste and simplifies the cost structure by eliminating additional substrates, especially in wafer-level CSP packaging.

CSP technology enables more compact product designs and provides superior focusing performance compared to COB (Chip-On-Board) technology, ensuring that light beam patterns comply with international standards.

However, CSP chips face significant challenges, particularly in assembly. The small size and fine pitch of CSP packages require high-precision surface mount equipment, which may be challenging for smaller-scale manufacturers to handle.

| Pros | Cons |

| Compact design Reduced material waste High brightness and performance | Complex assembly High equipment requirements |

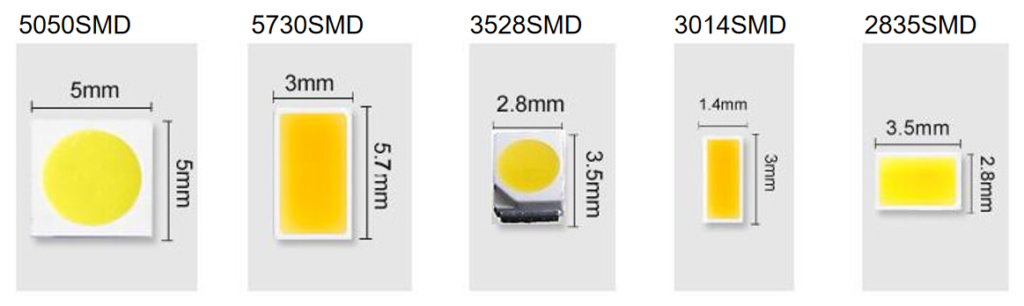

Understanding LED Chip Sizes

When exploring LED headlight bulbs, you might see numbers like 1860 or 3570. These numbers refer to the dimensions of the circuit board where the LED chip is mounted. For example, a 1860 chip has a board size of 1.8mm × 6.0mm, while a 3570 chip has a board size of 3.5mm × 7.0mm.

Contrary to popular belief, a larger number does not necessarily mean higher brightness. The size number only indicates the board’s dimensions, not the chip’s brightness. For instance, a 1mm × 1mm chip on a 3.5mm × 7.0mm board might still be labeled as a ‘3570 chip’ but could be dimmer.

The actual brightness of an LED chip depends on its specifications, not the board size. Key to understanding brightness is the MIL measurement, which denotes chip area. Higher MIL values generally mean greater power and brightness.

Common MIL sizes include:

1mil = 0.0254mm

43mil ≈ 1.1mm

45mil ≈ 1.15mm

55mil ≈ 1.4mm

75mil ≈ 1.9mm

80mil ≈ 2mm

In automotive lighting, different chip sizes and configurations affect power output. Examples include:

1860 Chip: Configurations like 3×43mil or 3×55mil

3570 Chip: Configurations like 3×55mil, 6×45mil, or 8×55mil

4575 Chip: Configurations like 6×77mil

5585 Chip: Configurations like 6×80mil

For accurate brightness assessment, focus on the LED chip’s specifications rather than just the circuit board size.

High-Power LED Headlight Bulbs for Cars

HILOWBIN V12 LED Headlight Bulb

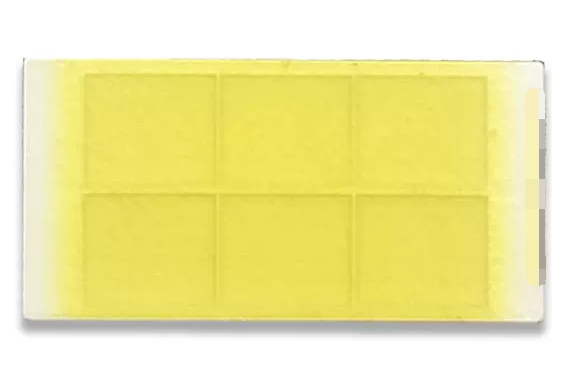

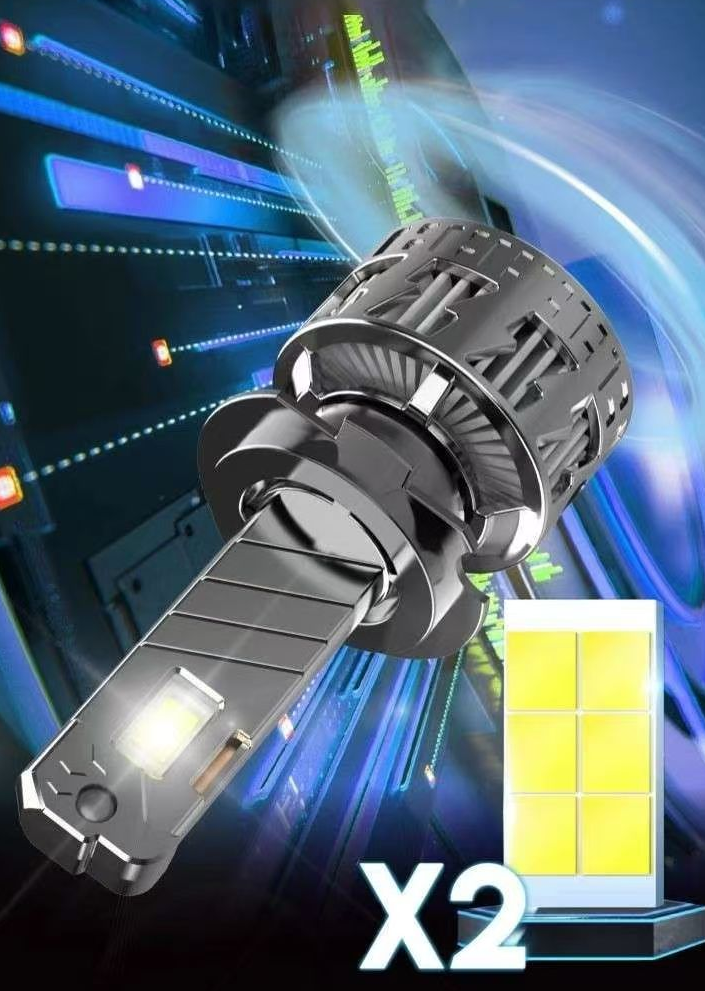

HILOWBIN V12 LED bulbs are designed with large 3575 model CSP chips that output 200 watts and 20,000 lumens of high brightness per set. These high-performance CSP chips ensure a focused and uniform beam of light, helping drivers achieve a wider, clearer field of vision while driving. 6500K cool white light provides a stable illumination effect, dramatically improving driving safety, and is ideal for replacing the factory halogen bulbs.

The HILOWBIN V12 LED bulb features 12 high-brightness csp chips (6 on each side), delivering exceptional lighting performance. Its dual-copper heat dissipation system can transfer up to 30W of heat per cycle, effectively enhancing cooling efficiency and ensuring the bulb maintains stable performance and a long lifespan even under intense use.

Conclusion

Various types of LED chips offer distinct benefits and constraints. Selecting the appropriate chip is crucial for meeting the specific needs of the lighting application and desired performance. For the best results in automotive LED lighting, it’s important to thoroughly evaluate the chip’s features and ensure efficient thermal management.