With the rapid development of LED headlight bulb technology, more and more people are familiar with the long lifespan, high brightness, and energy-saving characteristics of LED headlight bulbs. When looking for LED headlight bulbs, you may notice that some LED bulbs come with a small external box while others do not. Does this small box really matter to the LED headlight bulbs? This article will answer that question for you.

Types of LED Headlight Bulb Drivers

LED headlight bulb drivers (also known as LED power suppliers) are similar to ballasts. They provide the correct current for LED bulbs to operate and perform at their best. There are two main types of automotive LED headlight drivers: Integrated Driver and External Driver.

Integrated Driver

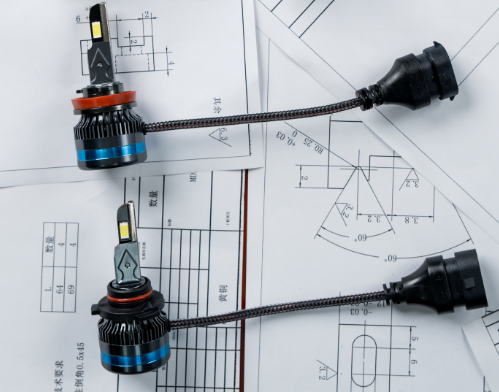

Some all-in-one designed LED headlight bulbs on the market look compact and are very convenient for installation.

Do they have a driver? Yes, they do. All LED headlight bulbs have an IC driver to operate the LED headlight bulb and control the forward current. For all-in-one designed LED headlight bulbs, manufacturers have integrated the driver with the LED bulb, so you can only see the LED bulb, wire, and plug.

External Driver

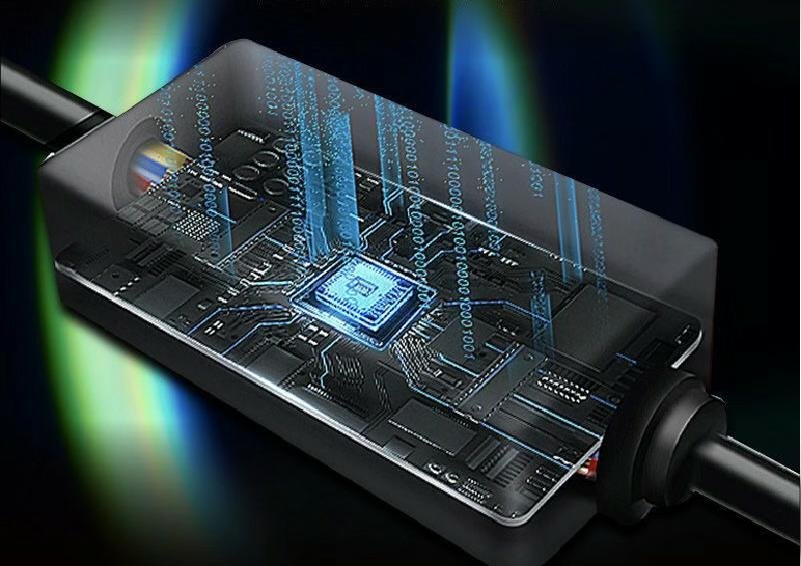

The small square box on the LED car headlights is the external driver, which is designed to meet the electrical requirements of the LED. Many LED drivers have protection features such as short circuit protection, overheat protection, and overvoltage protection. These functions can automatically turn off the power in abnormal situations, protecting the LED bulb and the entire circuit system.

Observing the picture, we can see that the LED headlight bulb plug is first connected to the driver, and then to the lamp body.

LED Headlight Driver Circuit Board Display

Here is the PCB(Printed Circuit Board) of the LED headlight bulb driver. It is a thin board made of various materials used to electrically connect electronic components. LED headlight bulbs use these boards to function effectively.

Comparison: Integrated Driver VS. External Driver

Design Difficulty

Integrated Driver:More Difficult to Design

The design of integrated driver LED bulbs is limited by the bulb base (LED headlight aluminum finned radiator). Therefore, it must be repeatedly tested to ensure the electronic circuit is in the correct direction and the layout of components such as capacitance, resistors, inductance, control IC, etc., is correct. Even a slight mistake can prevent installation. Integrated drivers have higher processing technology requirements, which can be a barrier for many small LED headlight factories. Only a few large headlight bulb manufacturers with strong creativity and productivity can manufacture high-performance integrated PCB drivers.

External Driver: Easier to Design

The external driver has additional space to place components. Therefore, components such as the diode, MOS tube, and resistance have relatively loose space to layout, and the manufacturing process requirements are not so high. Because they are easier to produce, most LED bulbs on the market come with an external driver.

Power

LED headlight bulbs with an external driver are designed with higher power than LED headlight bulbs with a built-in driver. Integrated headlight bulbs have a driver inside their body, which could cause heat dissipation pressure. Thus, it is better to design these integrated bulbs with lower power.

Installation

Integrated driver LED headlights are space-saving and easier to install. All-in-one designed LED headlight bulbs are equipped with a built-in driver. They are more compact and have a smaller bulb size, making them easy to install into the headlight housing and leaving enough room to close the dust cover. These all-in-one designed LED bulbs are beneficial to air circulation inside the headlight housing.

External driver need enough space to place the Canbus driver inside the headlight housing. If the driver is designed too large, it could be difficult to install for some medium or small headlight housing.

Heat Dissipation

Both external driver and integrated driver LED headlight bulbs are equipped with high-speed fans for active cooling.

However, the heat dissipation of LED headlight bulbs with an external driver is better than that of the integrated driver LED headlight bulbs. You can imagine the PCB working in a hot oven for the built-in driver, whereas the external driver works at room temperature.

Maintenance and Replacement

If the internal driver of the LED headlight bulb fails and needs repair or replacement, it will be more complex and difficult compared to an external driver.

Conclusion

Both internal and external drives must contain consistent electronic components. When the LED bulb is lit, these electronic components rapidly heat up to about 80 ° C. This means that the cooling system of the LED headlamp needs to handle the heat generated by the LED as well as the additional heat from the driver.

In this case, LED headlight bulb manufacturers must increase the radiator volume or install a higher speed fan to handle the extra heat. In addition, they can also reduce the forward current and lumen output to reduce the total heat generated by LED chips and electronic components.

if there are two LED headlights, one is an integrated LED headlight, and the other is an LED headlight with an external driver, their bulb size, cooling system and components are the same. LED headlight bulbs with external drivers can be designed to have a higher output to produce brighter light. However, LED bulbs with integrated designs tend to be more stable than the former.

Advanced LED Headlight Bulb with Internal Driver

HILOWBIN V8 Series LED Headlight Bulb

As mentioned above, integrated PCB driver boards require high design power and processing capability, with a high entry barrier.

The HILOWBIN V8 series LED headlight bulbs feature integrated PCB driver boards, built-in 12,000 RPM cooling fans, liquid-cooled copper pipes, and finned heat dissipation systems, demanding higher design and manufacturing capabilities.

These V8 LED bulbs provide excellent road illumination with 100 watts per pair and 12,000 lumens brightness, ensuring long lifespan and reliable performance with their stable power output and efficient cooling design.

Error-Free Products

V8 LED headlight bulbs are equipped with an intelligent Canbus driver, making them compatible with your vehicle’s advanced computer system. These bulbs can intelligently and safely increase the current without causing damage. V8 LED headlight bulbs are suitable for over 98% of vehicles. Here are the problems that the Canbus driver can solve:

(1) Vehicle dashboard warnings

(2) Radio interference

(3) Bulb flashing when turning on