Many car owners choose to upgrade to LED headlights because of their high efficiency, energy savings, brightness, and sustainability. However, a major drawback of LED headlights is the significant heat they generate. To address this issue, there are two main cooling mechanisms available on the market: with fan and fanless. Both aim to effectively dissipate heat, ensuring stable performance and long-term light output.

This blog will discuss in detail the pros and cons of with fan and fanless LED headlight bulbs to help you make an informed decision. This will not only enhance driving safety but also extend the lifespan of your headlights, providing a better driving experience.

Why do LED headlight bulbs need good thermal management?

Many people think that LED headlight bulbs, which are known for their energy efficiency, do not generate much heat. However, this is a misunderstanding. LED headlight bulbs do generate heat, and they require effective thermal management. The reasons are as follows:

Increase the Life of the Bulb

LED bulbs are more durable than traditional halogen bulbs, but excessive temperature can shorten the life of the LED chip. When LED bulbs operate at high temperatures, the semiconductor material inside them will gradually degrade, resulting in reduced light output and ultimately affecting the life of the bulb. Effective thermal management ensures that the LED chip operates within a safe temperature range, thereby extending its service life.

Maintain Stable Light Output

The light output of an LED bulb is closely related to its operating temperature. High temperatures can cause the light efficiency of LED bulbs to decrease, and brightness attenuation may occur even in a short period of time. Good thermal management can maintain the stable light output of LED bulbs, ensuring brightness consistency over long periods of use.

Improve Energy Efficiency

Excessive temperature affects the energy efficiency of LED bulbs, leading to increased energy consumption. This is because LED chips work less efficiently at high temperatures, with more energy converted to heat rather than light. Effective thermal management optimizes the energy efficiency of LED bulbs, allowing them to provide high brightness while maintaining low energy consumption.

Improve Overall Performance

Thermal management affects not only the life and light output of LED bulbs but also their overall performance. For example, improper thermal management can cause flicker, light attenuation, color shifts, and other issues in the bulb. By optimizing thermal management, you can ensure that LED bulbs work stably in various environments, providing the best lighting results.

Advantages and Disadvantages of Fan and Fanless LED Headlight Bulbs

When choosing LED headlight bulbs, it is crucial to understand the advantages and disadvantages of fan and fanless bulbs. They differ significantly in terms of heat dissipation, brightness, energy efficiency, and maintenance.

Advantages and Disadvantages of Fan LED Headlight Bulbs

Advantages:

High Brightness: With fan cooling, fan LED headlight bulbs can consume additional power and increase overall brightness without burning out the bulbs, making them suitable for high-brightness lighting scenarios.

Good Heat Dissipation: The built-in high-speed fan can quickly remove heat from the LED chip, effectively lowering the temperature and extending the bulb’s lifespan.

Compact Structure: The fan is integrated into the bulb, requiring minimal space, making it suitable for vehicles with limited installation space.

Simple and Stable Design: The integrated fan design results in a relatively simple and stable structure.

Maintained High Performance: The high-speed fan effectively removes heat from the bulbs, maintaining the high performance of the LED bulbs.

Disadvantages:

High Power Consumption: The fan requires additional power to operate, resulting in higher overall power consumption.

Noise Issues: The fan can generate a lot of noise within the headlight assembly during the cooling process, affecting the driving experience.

High Maintenance Costs: The fan may fail and require regular checks and maintenance. Purchasing inferior LED bulbs may lead to fan damage, increasing maintenance costs.

Potential Failures: If inferior LED bulbs are purchased, the fan may break, adding to maintenance costs.

Advantages and Disadvantages of Fanless LED Headlight Bulbs

Advantages:

Energy Saving: Without the need for additional power to operate a fan, fanless LED bulbs are more energy-efficient than those with fans.

No Noise: Without a fan, there is no operational noise, providing a quiet driving experience.

Long Lifespan: With no mechanical parts (fans), the failure rate is low, resulting in a longer lifespan and reduced need for frequent maintenance.

Low Maintenance Costs: Fanless LED bulbs are less susceptible to dust and water damage, making maintenance costs relatively low.

Disadvantages:

Relatively Low Brightness: Fanless LED bulbs may not be as bright as fan-cooled LED bulbs.

Poorer Heat Dissipation: Relying on natural heat dissipation, the cooling speed is not as fast as fan-cooled LED bulbs, which may affect long-term stability.

Slightly Complex Structure: To effectively dissipate heat, fanless LED bulbs are usually equipped with larger heat sinks, resulting in a more complex structure and occupying more space.

By understanding these comparisons, users can choose the most suitable LED headlight bulbs based on their needs and actual situations.

Cooling method of Fan and Fanless LED Headlight Bulb

Cooling method of LED headlight bulb with fan

LED headlights with fans have an active cooling system. The system has a small built-in fan that quickly takes away the heat generated by the LED bulb through forced air flow. The high-speed rotation of the fan effectively reduces the operating temperature of the bulb, keeping it within a safe range. The fan is installed inside the heat sink of the LED bulb, the structure is stable and durable, and it can efficiently dissipate heat in a confined space. This cooling design involves the heat transfer of aluminum and copper substrates, so the operating cost will be relatively higher than that of the fanless design. In addition, some quality LED headlight bulbs are equipped with copper heat pipes to transfer heat faster and more efficiently.

Fanless LED headlight bulb cooling method

LED headlights without fans use a passive cooling system. The heat sink of the high-quality fanless LED bulb provides a high level of heat dissipation, utilizing natural wind to relieve heat by achieving high efficiency. There are no moving parts in the passive cooling system, so no noise is generated and maintenance costs are low. High-quality fanless LED bulbs are optimized for heat dissipation, providing effective cooling without relying on a fan in well-ventilated or low-power applications.

Different types of active cooling

High brightness LED headlight bulbs are mostly equipped with fans to dissipate heat. In fact, the active cooling mechanism is also different, which can be mainly divided into three forms: hydraulic fan heat dissipation,turbofan heat dissipation, double ball bearing fan heat dissipation.

Hydraulic fan

Hydraulic fan cooling dissipates heat through the movement of a liquid medium. This technology features a unique spiral groove carved into the bearing. As the bearing rotates, lubricating oil is evenly distributed to reduce friction and noise. The advantages of hydraulic fans include low noise and long lifespan, with an average lifespan reaching up to 40,000 hours, making them widely used in LED headlight bulb cooling. However, as the usage time increases, the lubricating oil gradually evaporates, leading to wear and reduced lifespan.

Turbofan

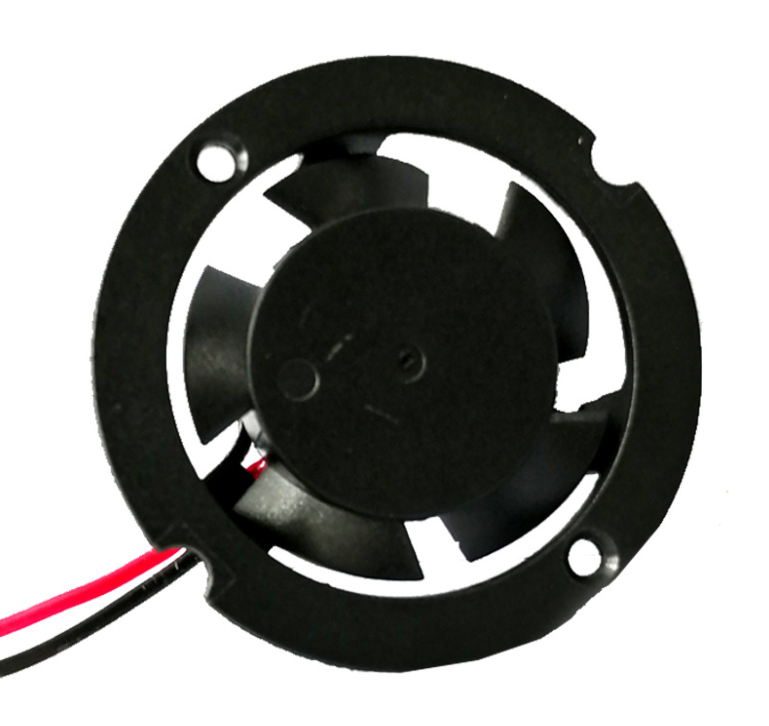

Turbofan cooling uses a design similar to a turbocharger, where high-speed fan blades quickly dissipate heat. The motor drives the impeller to rotate, throwing airflow around the impeller and creating a pressure difference. New air is drawn into the impeller due to this pressure difference and then continuously expelled from the fan. The advantages of turbofans are that they can produce fast airflow in small spaces, achieving high cooling efficiency. However, turbofans require high design standards and higher machining precision than ordinary fans. When dust adheres to the blades, it can affect the speed, causing imbalance and increased noise.

Double ball bearing

Dual ball-bearing fans use two ball bearings to dissipate heat through rolling friction. This design includes several small steel balls in the bearings surrounding the shaft. When the fan rotates, the steel balls also rotate. The advantages of dual ball-bearing fans are their longer lifespan, which can exceed 50,000 hours, good aging resistance, high rotational speed, and sufficient airflow. However, these fans are more expensive to manufacture and are the noisiest at the same speed.

Best Fanless LED Headlight Bulb

HILOWBIN V3 LED Headlight Bulb

If you’re bothered by fan noise, or you’re on a limited budget. You may be better suited for a fanless LED headlight bulb. HILOWBIN V3 LED headlight bulbs combine bulb brightness and fanless design. HILOWBIN is a reliable supplier of headlight bulbs, and HILOWBIN V3 series LED headlight bulbs are made of an integrated aviation aluminum lamp body to achieve the best possible heat dissipation. It also has a sustainable output of 70 watts (a pair of bulbs), providing a broad and bright light to illuminate your path.

Best LED headlight bulb with fan

HILOWBIN M35 LED Headlight Bulb

Most LED headlight bulbs use cooling fans and aluminum radiators to dissipate heat. The new M35 LED bulb is equipped with a 12000RPM high-speed silent fan and adds four copper heat pipes inside the bulb, each of which can transfer 20W of heat for effective cooling. No more worrying about LED lights melting your dust cover.

With better thermal management, the M35 LED headlamp bulb can carry 200W of high power, 24,000 lumens, and achieve long-lasting high brightness without damaging your headlamp system.

FQAs

Q1:Is it normal for LED headlights to feel very hot after a few minutes of lighting?

This is normal because LED headlights generate heat when they work normally. The bottom of the LED headlight is cooling, keeping the temperature within the normal range. Be careful not to touch the bulb directly with your hands and take protective measures!

Q2:Will LED headlight bulbs melt the housing?

Whether an LED bulb will melt the headlamp bulb housing depends on a number of factors, such as the installation method, heat dissipation design and the LED bulb power used. If LED bulbs are installed correctly and have proper heat dissipation measures in place, the heat they generate will not usually cause the headlamp housing to melt. Even poor quality LED headlights won’t be hot enough to melt the housing, but will overheat and have a much shorter life.

Q3:Do LED headlights consume less power than halogen headlights?

Yes,LED headlights can transfer 80% of the energy into light with less energy waste, while halogen headlights can only transfer 20% of energy into light. LED headlights are more energy-efficient. For example, to produce around 2000 lumens of light, LED bulbs will draw 20 watts while halogens will draw 125 watts.